- Accueil

- filet de plot

- Modeling, analysis, and multi-objective optimization of cold extrusion process of clutch outer gear hub using response surface method and meta-heuristic approaches

Modeling, analysis, and multi-objective optimization of cold extrusion process of clutch outer gear hub using response surface method and meta-heuristic approaches

4.5 (92) · € 33.00 · En Stock

Modeling, analysis, and multi-objective optimization of cold extrusion process of clutch outer gear hub using response surface method and meta-heuristic approaches

Multi-objective shape optimization of large strain 3D helical structures for mechanical metamaterials - ScienceDirect

Energies, Free Full-Text

Multi-objective shape optimization of large strain 3D helical structures for mechanical metamaterials - ScienceDirect

Multi-objective optimization of GFRP injection molding process parameters, using GA-ELM, MOFA, and GRA-TOPSIS

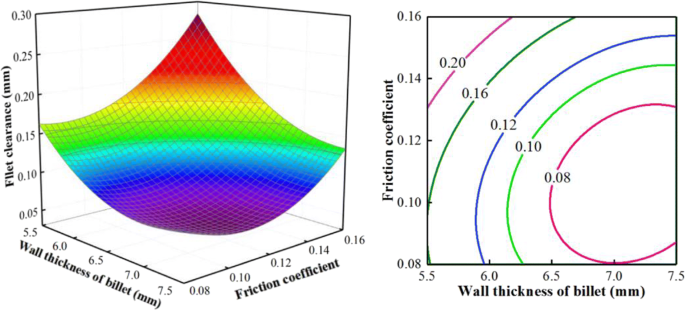

Modeling, analysis, and multi-objective optimization of cold extrusion process of clutch outer gear hub using response surface method and meta-heuristic approaches

Numerical simulation and experimental study on cold extrusion process for clutch outer gear hub with inner tooth shapes

Processes, Free Full-Text

Action Recognition, Tracking, and Optimization Analysis of Training Process Based on SVR Model and Multimedia Technology

Modeling and optimization of cold extrusion process by using response surface methodology and metaheuristic approaches

Modeling and optimization of cold extrusion process by using response surface methodology and metaheuristic approaches

Applied Sciences, Free Full-Text

Modeling and optimization of cold extrusion process by using response surface methodology and metaheuristic approaches

Zuofa LIU, Doctor of Engineering, Chongqing University, Chongqing, CQU, School of Material Science and Engineering

Modeling, analysis, and multi-objective optimization of cold extrusion process of clutch outer gear hub using response surface method and meta-heuristic approaches